Golden Far East Machinery Co.,Ltd.

Manufacturing Plastic Machinery Factory

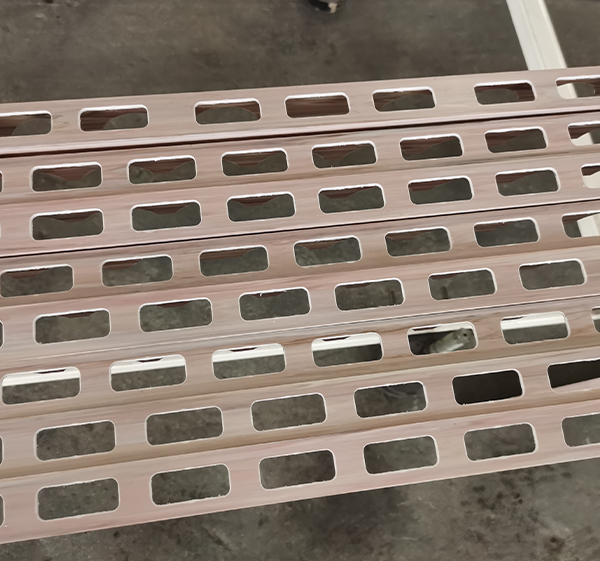

Because the PVC profile corner is most likely to be damaged during the construction and completion of the building, the use of corner strip strengthens the firmness of the wall, and can save a lot of time because of its easy construction. The corner protection strip is fast and convenient for construction, strengthens the wall corner strength, and has wide practicability. The corner protection strip has the advantages of corrosion resistance, impact resistance, anti-aging, good adhesion and full combination with putty, which greatly enhances the impact resistance of the wall corner, maintains the long-term beauty of the wall corner without being damaged, and can be constructed simultaneously with the main project. There is no need to use the guiding ruler plate in the use process, the operation is simple, the construction efficiency is 2-5 times that of the general, simplifies the construction procedure and speeds up the construction speed, The project cost is reduced and the project quality is improved.

PVC corner strip is a new type of building material specially designed for the difficult construction of wall corner, door edge strip and window corner. It is characterized by its unique environmental protection, weathering resistance and aging resistance. Its strength and toughness have made people replace steel, wood, aluminum and other traditional building materials safely. We use corner protection to cover up the lack of technology and bind the wall corners up, down, left and right. Even if a single benzene plate is accidentally cracked, it is difficult to affect the large-area falling off of the whole system. After using PVC strips, you can't do it straight, because the thickness and size of our products are unified, and we carry 10cm grid cloth, which eliminates the complex locking process of reverse wrapping of grid cloth, increases the impact resistance of wall corners, and the perpendicularity and levelness of wall corners are very easy to achieve. In addition, it prolongs the service life of external wall insulation and improves the quality of buildings. Keep the corner permanently beautiful.

This project is the first time that the customer company has done it. Fortunately, the customer readily ordered equipment with us in the second week of connecting each other.

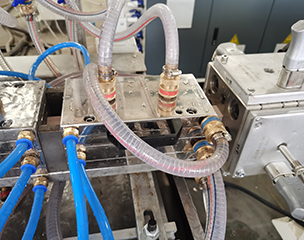

PVC corner profile production line includes: single screw extruder, mould, vacuum calibration table, haul-offs, on-line punching machine and cutting machine.

Extruder model: SJ65 / 25 Single screw extruder motor power: 22kw